Skip to product information

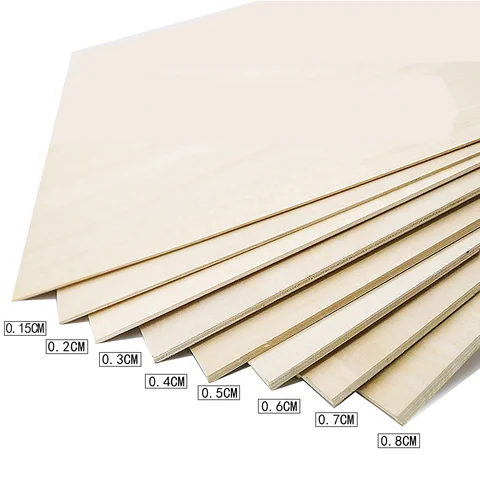

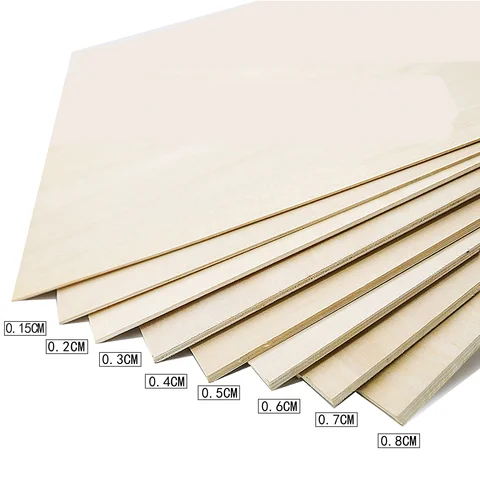

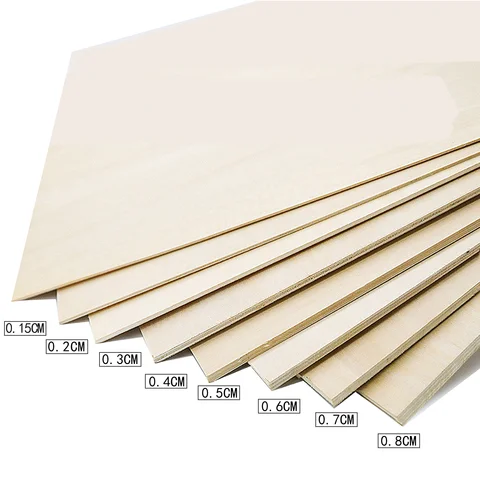

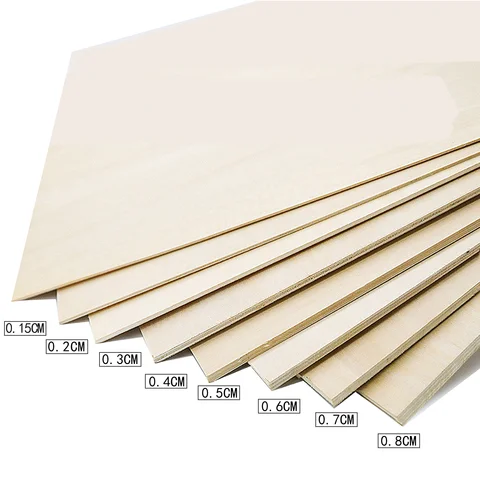

Lexie Wood Laser Plywood

₱1,249.00 PHP

Pickup currently not available

Bass plywood

3mm thick and 6mm thick 4ftx8ft

free laser cutting up to 8pcs cut max

Laser Cutting Plywood: The Ultimate Guide for Hobbyists and Pros

Introduction to Laser Cutting Plywood

Laser cutting plywood is a precise and efficient method used for crafting, DIY projects, and professional applications. This technique involves using a laser beam to cut or engrave plywood, producing clean and intricate designs that are difficult to achieve with traditional tools.

Choosing the Right Laser and Settings for Plywood

Types of Lasers:

- Diode Lasers (5W & 10W): Best for thinner plywood (up to 3mm). Multiple passes might be needed for a clean cut.

- CO2 Lasers (40W and above): Ideal for thicker plywood (up to 10mm). Capable of cutting through with fewer passes and providing a smoother finish.

Recommended Settings:

- 5W Diode Laser: 2 passes at 100% power and 10 mm/s speed for 1.5mm basswood.

- 10W Diode Laser: 1 pass at 100% power and 9 mm/s speed for 1.5mm basswood.

- 40W CO2 Laser: 1 pass at 23% power and 15 mm/s speed for 1.5mm basswood

Essential Techniques for Laser Cutting Plywood

Using Air Assist

- Benefits: Enhances cutting efficiency, reduces char marks, and helps prevent fires. Recommended air pressure is between 30-50 psi

Safety Measures

- Ventilation: Essential to avoid inhaling harmful fumes.

- Proper Focus and Cleanliness: Ensures optimal cutting performance and reduces fire risks.

- Avoid Over-Powering: Too much power can cause excessive burning and potential fires

Advanced Finishing Techniques

Reducing Burns:

- Masking Tape: Apply to the plywood surface to minimize burns during engraving.

- Sanding: Use sandpaper to clean edges and remove charred material.

- Denatured Alcohol: Ideal for fine engraving cleanup without damaging the plywood

Troubleshooting Common Issues

Incomplete Cuts:

- Increase Power: If the laser isn't cutting through, increase the power or number of passes.

- Adjust Focus: Ensure the laser is properly focused on the material.

- Clean Optics: Dirty optics can reduce laser effectiveness

Burn Marks and Fire Risks:

- Use Air Assist: Prevents burn marks and helps control the cutting temperature.

- Proper Speed Settings: Adjust laser speed and power to balance cutting efficiency and burn prevention

Pros and Cons of Laser Cutting Plywood

Pros:

- High Precision: Achieves intricate and detailed cuts.

- Versatile: Suitable for various projects from simple cuts to complex engravings.

- Readily Available: Plywood is a common and versatile material for laser cutting

Cons:

- Thickness Limitations: Not suitable for very thick plywood.

- Fire Hazards: Requires careful handling and proper safety measures.

- Char Risk: Edges can burn if not properly managed

Best Practices for Laser Cutting Plywood

- Test Settings: Always start with a test piece to fine-tune your laser settings.

- Use Quality Plywood: Choose plywood with low resin content for best results.

- Regular Maintenance: Keep your laser cutter clean and well-maintained to ensure consistent performance.